Desuperheater Water Heater - Manor

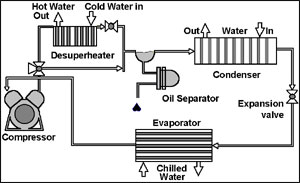

Manor desuperheater water heater is a unique heat exchanger that generates hot water/ fluid to the maximum temperature of 80℃. The water / fluid can be heated by recovering the superheat of the refrigerant gas which is otherwise wasted to the atmosphere through air/ water cooled condensers. The heat is recovered with almost zero operating cost.

Desuperheater Operation:

| Compressor Type | Discharge Temperature |

|---|---|

| Screw (Indirect cooled) | 70 to 80℃ |

| Screw (Injection cooled) | 50 to 60℃ |

| Reciprocating | 85 to 110℃ |

| Boosters (Rotary & Reciprocating) | 75 to 85℃ |

In a usual AC & R system, the refrigerant temperature rises in tune of 80℃ to 120℃ after compression. The refrigerant is further put to the air/ water cooled condenser to condense near about 40℃.

While the condensing of refrigerant in the condenser, the total heat contained in this high Temperature/high pressure gas gets wasted to the atmosphere.

This superheat of the gas which is part of the total heat content of the gas, has a substantial heat potential provided the same is reclaimed efficiently and is optimized for energy saving

Manor Desuperheater Water Heater is the ultimate accessory for an AC & R plant that can be used to remove superheat of the refrigerant.

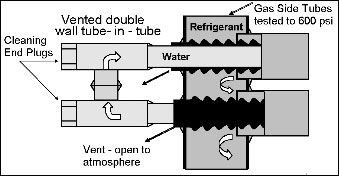

Desuperheater Design:

Double Walled " Tube in Tube ", vented, counter flow heat exchanger. Vent tube having serrations on inner & outer surfaces to avoid cross contamination of refrigerant and water/ fluid. Each tube has a tube inside that allows water/ fluid to travel in an opposite direction.

Desuperheater Installation:

The Desuperheater Water Heater is installed before the condenser and the oil separator. The refrigerant travels through the series of tubes in the Desuperheater before entering the condenser. Normally the Desuperheater Water heater is designed considering the hot water requirement for the processes. When needs of hot water & refrigeration are not simultaneous, a " Recirculation " type system is provided wherein hot water is generated, stored & maintained in an insulated tank. This hot water then can be utilised as and when required.

The Desuperheater water heater can be easily retrofitted on reciprocating, scroll or screw type chillers.

Desuperheaters Types :

Freon Desuperheater - SERIES HEF 33- XXX- 22 :

| Dimensions | |||||||

|---|---|---|---|---|---|---|---|

| Models | System TR | Width mm | Length mm | Height mm | Gas pipe Inlet & Ootlet Size | Water pipe Inlet & Ootlet Size | Weight Kg |

| HEF 33-10-22 | 10 | 70 | 1240 | 660 | 1 1/8" | 1 1/8" | 36 |

| HEF 33-20-22 [M] | 12 | 120 | 1295 | 462 | 1 5/8" | 1 5/8" | 55 |

| HEF 33-30-22 [M] | 18 | 170 | 1295 | 462 | 2 1/8" | 2 1/8" | 82 |

| HEF 33-40-22 [M] | 24 | 225 | 1295 | 462 | 2 1/8" | 2 1/8" | 82 |

| HEF 33-30-22 | 30 | 170 | 1295 | 660 | 2 1/8" | 2 1/8" | 109 |

| HEF 33-50-22 [M] | 30 | 273 | 1295 | 462 | 2 1/8 " | 2 1/8 " | 137 |

| HEF 33-60-22 [M] | 36 | 323 | 1300 | 462 | 2 5/8" | 2 5/8" | 164 |

| HEF 33-40-22 | 40 | 225 | 1295 | 660 | 2 1/8" | 2 1/8" | 145 |

| HEF 33-70-22 [M] | 42 | 374 | 1300 | 462 | 2 5/8" | 2 5/8" | 191 |

| HEF 33-80-22 [M] | 48 | 425 | 1300 | 462 | 2 5/8" | 2 5/8" | 218 |

| HEF 33-50-22 | 50 | 273 | 1300 | 660 | 2 1/8 " | 2 1/8 " | 182 |

| HEF 33-90-22 [M] | 56 | 480 | 1300 | 462 | 2 5/8 " | 2 5/8 " | 246 |

| HEF 33-100-22 [M] | 60 | 530 | 1300 | 462 | 3 1/8 " | 3 1/8 " | 273 |

| HEF 33-60-22 | 60 | 323 | 1300 | 660 | 2 5/8 " | 2 5/8 " | 218 |

| HEF 33-110-22 [M] | 66 | 580 | 1300 | 462 | 3 1/8 " | 3 1/8 " | 300 |

| HEF 33-70-22 | 70 | 374 | 1300 | 660 | 2 5/8 " | 2 5/8 " | 255 |

| HEF 33-120-22 [M] | 72 | 630 | 1300 | 462 | 3 1/8 " | 3 1/8 " | 327 |

| HEF 33-130-22 | 78 | 680 | 1300 | 462 | 3 5/8 " | 3 5/8 " | 354 |

| HEF 33-80-22 | 80 | 425 | 1300 | 660 | 2 5/8 " | 2 5/8 " | 290 |

| HEF 33-140-22 [M] | 84 | 730 | 1300 | 462 | 3 5/8 " | 3 5/8 " | 382 |

| HEF 33-150-22 [M] | 90 | 780 | 1300 | 462 | 3 5/8 " | 3 5/8 " | 409 |

| HEF 33-90-22 | 90 | 480 | 1300 | 660 | 2 5/8 " | 2 5/8 " | 328 |

| 328HEF 33-160-22 [M] | 96 | 830 | 1300 | 462 | 3 5/8 " | 3 5/8 " | 437 |

| HEF 33-100-22 | 100 | 530 | 1300 | 660 | 3 1/8 " | 3 1/8 " | 364 |

| HEF 33-170-22 [M] | 102 | 880 | 1300 | 462 | 3 5/8 " | 3 5/8 " | 458 |

| HEF 33-180-22 [M] | 108 | 930 | 1300 | 462 | 3 5/8 " | 3 5/8 " | 491 |

| HEF 33-110-22 | 110 | 580 | 1300 | 660 | 3 1/8 " | 3 1/8 " | 400 |

| HEF 33-120-22 | 120 | 630 | 1300 | 660 | 3 5/8 " | 3 5/8 " | 436 |

SERIES HEF 33- XXX- 22 : CONSTRUCTION DETAILS :

| DESIGN | Double walled “ Tube in Tube “, vented, counter flow heat exchanger. Vent tube having serrations on inner & outer surface |

| MATERIAL OF CONSTRUCTION | |

| HEADERS | Seamless MS/ Cast Steel/ SS 304 |

| WATER PIPES | Copper |

| VENT TUBE & GAS PIPE | SS 304/ Copper |

| INSULATION | 1 " Fiber Glass/ Glass Wool Insulation/ Rubberised foam " |

| CLADDING | ASTM A 351, Gr. CF8M |

| END CONNECTIONS | Flanged Ends as per ANSI B16.5, Class 150 |

| GAS LINE | 24 kg/ cm2 |

| WATER LINE | 10 kg/ cm2 |

| MOUNTING POSITION | Vertical & in Upward Direction |

RECOVERABLE SUPER HEAT FROM R-22 SYSTEMS :

| Condensing Temperature °C | Estimated Discharge Temperature °C | Recoverable Heat Kcal/ hr/ kw |

|---|---|---|

| 46 | 82 | 1875 |

| 43 | 77 | 1700 |

| 31 | 71 | 1650 |

| 35 | 66 | 1500 |

AMONIA DESUPERHEATER - SERIES HEA 77- XXX- 717 :

| Dimensions | |||||||

|---|---|---|---|---|---|---|---|

| Models | System TR | Width mm | Length mm | Height mm | Gas pipe Inlet & Outlet Size | Water pipe Inlet & Outlet Size | Weight Kg |

| HEF 77-15-717 | 15 | 95 | 1750 | 400 | 1 1/4" | 5/8" | 30 |

| HEF 77-25-717 | 25 | 95 | 1750 | 700 | 1 1/4" | 5/8" | 50 |

| HEF 77-50-717 | 50 | 180 | 1750 | 700 | 2" | 3/4" | 75 |

| HEF 77-75-717 | 75 | 265 | 1750 | 700 | 2 1/2" | 3/4" | 100 |

| HEF 77-100-717 | 100 | 345 | 1750 | 700 | 2 1/2" | 1" | 125 |

| HEF 77-125-717 | 125 | 425 | 1750 | 700 | 3 " | 1 " | 150 |

| HEF 77-150-717 | 150 | 510 | 1750 | 700 | 3" | 1 1/4" | 175 |

SERIES HEF 33- XXX- 22 : CONSTRUCTION DETAILS :

| DESIGN | Double walled " Tube in Tube ", vented, counter flow heat exchanger. Vent tube having serrations on inner & outer surface |

| MATERIAL OF CONSTRUCTION | |

| HEADERS | Seamless MS/ SS 304 |

| WATER PIPES | SS 304/ SS 316L |

| VENT TUBE | SS 304/ SS 316L |

| GAS PIPE | MS/ Carbon Steel |

| INSULATION | 1" Fiber Glass/ Glass Wool Insulation/ Rubberised foam |

| CLADDING | ASTM A 351, Gr. CF8M |

| END CONNECTIONS | Flanged Ends as per ANSI B16.5, Class 150 |

| GAS LINE | 24 kg/ cm2 |

| WATER LINE | 10 kg/ cm2 |

| MOUNTING POSITION | Vertical & in Upward Direction |

RECOVERABLE SUPER HEAT FROM R-22 SYSTEMS :

| Condensing Temperature °C | Estimated Discharge Temperature °C | Recoverable Heat Kcal/ hr/ kw |

|---|---|---|

| 43 | 114 | 1990 |

| 41 | 104 | 1800 |

| 38 | 99 | 1730 |

| 35 | 91 | 1525 |

| 32 | 86 | 1450 |