ECONET

Introduction of ECONET:

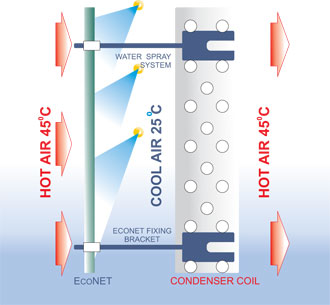

ECONET concept is based on intermittently and efficiently evaporating water on a large area in front of the heat rejection surface of Mini - Split, Rooftop, Air Cooled Chillers, Condensers and Dry Coolers.

HOW DOES IT WORK ?

Water spray provides an adiabatic cooling effect of the incoming air stream and it can be either initiated via an ambient sensor or alternatively by refrigeration head pressure override i.e. condensing pressure limit. As soon as these settings exceed a pre-set level the ECONET controller initiates water spray in order to lower the air on temperature for the condenser, hence, the condensing pressure can be lowered in order to save energy during high ambient periods

FEATURES :

Water Spray System Quick change type plastic nozzles connected in series or parallel arrangement in order to provide uniform coverage area for an effective evaporation process. Nozzles are designed to operate with very low pressure and they can operate with normal city mains water pressure 1.5 Barg (21 psig) / ( 15m ) and above.

ECONET :

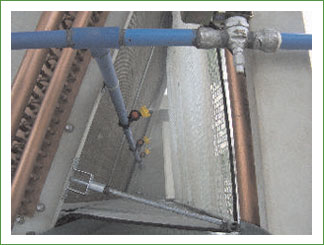

Non metallic mesh provides an effective coverage area for an efficient evaporation surface with minimal air pressure drop Meshes are fixed in front of the heat rejection surface via spacer bars and/or fixing brackets to suit the unit configuration. Various size sectional mesh panels are either joined together to form a full mesh area or alternatively flexible mesh roll cut to fit to a required size in front of the heat rejection surface. This design provides easy maintenance and replacement for the mesh panels.

FIXING BRACKETS :

Custom made brackets are designed to match any coil configuration They can be hooked from the coil tubes in the coil and mesh area. Spray nozzles are also fitted as part of the bracket arrangement .

CONTROLLER :

A custom made intelligent PLC based controller records the ambient conditions and at a pre set value, which is adjustable by the operator, initiates in-line solenoid valves(s)

Water is sprayed intermittently to wet the meshes. The spray rate and duration are adjusted by the controller to suit the ambient conditions, hence minimal water consumption. Water usage is based on total waste principal, hence, no health risk.

ECONET controller is provided with internal override terminals for a volt free input which overrides the temperature set limit and initiate intermittent spray as soon as this terminal is linked. This facility can be used to provide head pressure or manual remote override flexibility

ECONET PERFORMANCE DATA :

Water spray durations and frequencies are constantly adjusted by the ECONET intelligent controller in order to optimize the performance as well as minimize water consumption. The higher the ambient temperature longer the spray and the frequency of the spray is also increased to match the ambient conditions. Once the low ambient set point is reached the spray operation is automatically terminated.

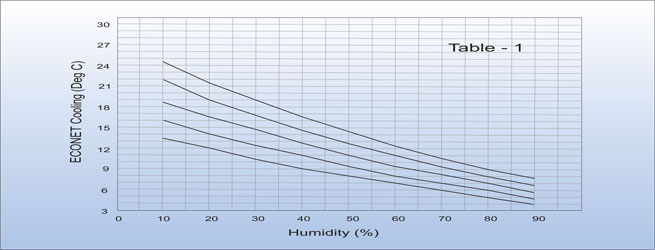

The adiabatic cooling process is entirely driven by the incoming air humidity and Table 1 indicates the incoming air cooling capability of an ECONET system based on humidity ratios against various ambient dry bulb conditions.

It is equally important to minimize the water wastage and ECONET controller's intelligent intermittent spray operation together with set point limit minimizes the water consumption as much as 75% in comparison to a comparable cooling tower, evaporative or any other adiabatic air cooling units.

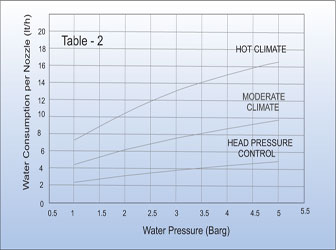

Table 2 indicates the average water consumption per nozzles against various operational conditions. Hot climate generally refers to Middle East and Mediterranean countries and Temperate Climate refers to moderate Central European type climate conditions. Head Pressure Control refers to high pressure override conditions which occurs only during very high ambient in order to overcome HP manual safety shutdown for the refrigeration system.

ECOMESH APPLICATIONS :

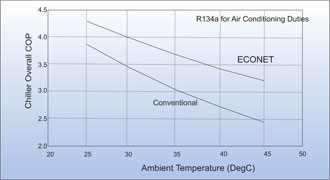

Air Cooled Chillers :

Any make or model or air cooled chillers, whether a new project or retrofit application can be easily converted to a wet system by means of either factory add on or site modification. The efficiency improvement in terms of COP is illustrated in the following graph

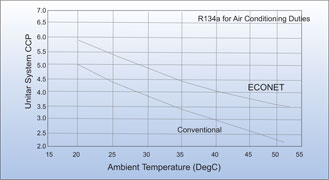

UNITARY PRODUCTS :

Unitary products such as Rooftop and Mini Split units rely ondry bulb only. If the unit is converted from dry bulb to wet bulb ambient operation condition by simply adding ECONET kit for the condenser, the output of the unit can be increased as much as 40 % Multiple units can be controlled from a single controller for a cost effective and easy to set up site installation for both new and retrofit applications.

AIR COOLED CONDENSERS & DRY COOLERS :

Air Cooled Condensers and Dry Coolers can be either Horizontal, Vertical, "V" or "W" configuration and ECONET can be fitted in any type or orientation for both New and retrofit applications. Some condenser manufactures are already offering ECONET as a factory fitted option. Large number of ammonia Air Cooled Condensers using ECONET instead of Cooling Towers or Evaporative Condensers have been successfully installed achieving maintenance and legionella free operation. Typically compressor COP improvement is illustrated in graph below.

AIR CONDITIONING APPLICATION :

Large numbers of air conditioning units from almost every make and model around the world have been successfully fitted with ECONET kits.

Systems installed so far indicated energy efficiency improvements of up to 45% with a maximum one cooling season pay back.

Even with poor water quality, nozzles and meshes have been operating for more than 4 years without any cleaning requirement.

REFRIGERATION APPLICATION :

ECONET has also been successfully applied for large scale air cooled condenser units for both HFC and Ammonia refrigeration operations around the world.

A number of condenser manufacturers have already incorporated ECONET as part of their standard range, and are offering both new and site retrofit kits. Refrigeration electrical loads are one of the main electrical intakes for many Food Processing Processes and Supermarket Refrigeration, so any saving in terms of energy is welcome news for the profitability.

Considering the large number of existing systems. ECONET offers a realistic alternative to reduce the electrical energy bills and minimize the impact of any future environment taxation. Data from a typical installation indicates O an air intake cooling of almost 10 C. This reduced condensing pressure resulted in a reduction of as much as 12 % of peak energy consumption. ECONET has also been successfully applied to overcome the old scaled condenser problems as in the case of Ashwini Hosptial , Solapur (INDIA) or applied from day one to minimize the energy consumption and improves compressor life as in the case of RISE N SHINE BIOTECH PUNE, (INDIA) and many other installations around the world.

TECHNICAL SUPPORT :

ECONET offers full system design support to assist in proper selection and integration into existing or new installations as part of our customer commitment.

Please consult out technical sales teal at : sales@manikengineers.com

for your specific application or visit our web site www.manikengineers.com